- Overview

- Inquiry

- Related Products

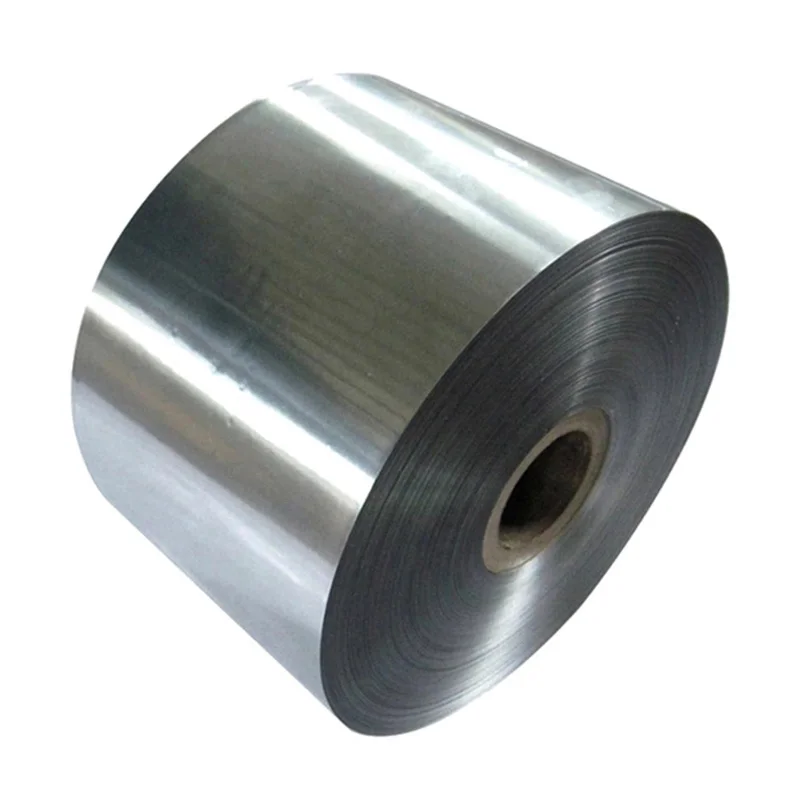

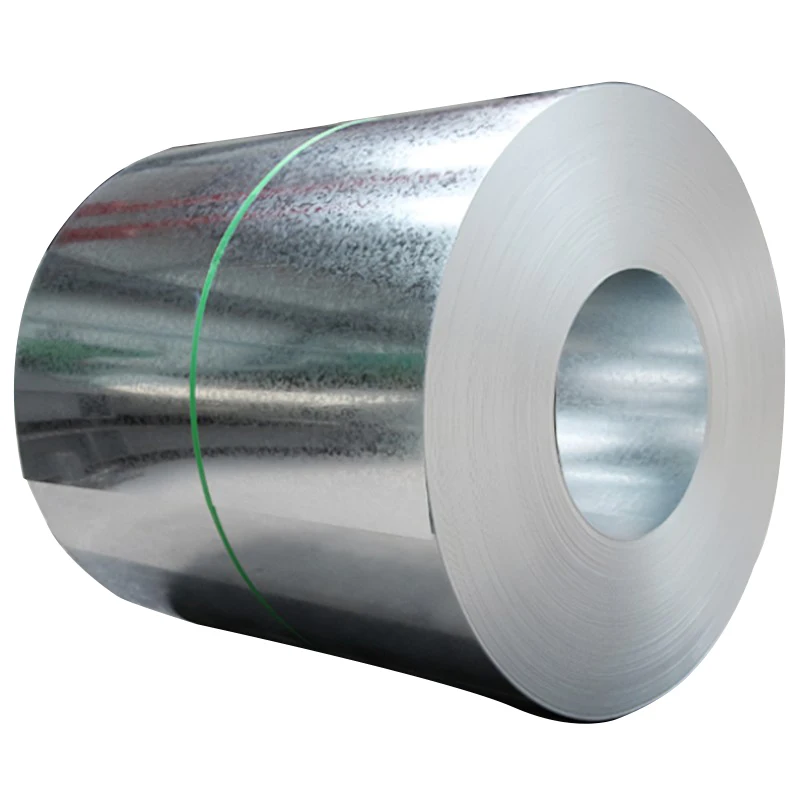

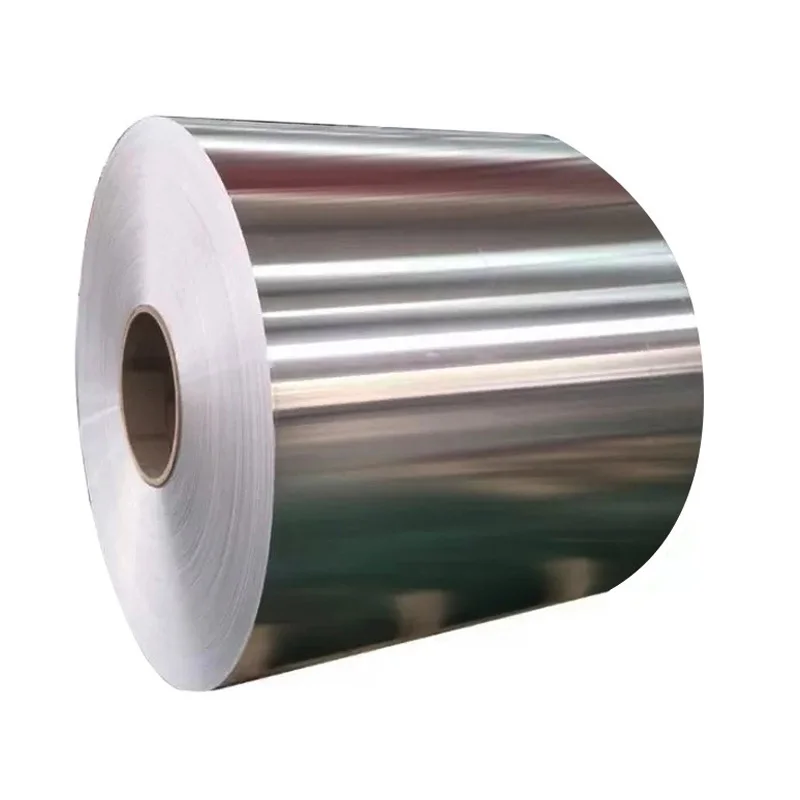

The Electrolytic Tinplate is just a item that is high-quality is widely employed in different companies. This sort of tinplate's is produced by electrolytically coating a layer that is thin of onto a metal sheet. The effect is just a sheet this is really both corrosion-resistant and sturdy.

Certainly, one of many popular top features of the Electrolytic Tinplate is its flexibility. The item may be used in regard to level of applications, including dishes and beverage packaging, electronic elements, construction materials, and other things. The tins finish additionally comes with an obstacle this is really dampness that is great that helps it is a variety that is popular products which need durable storage space.

The manufacturing procedure associated with the Electrolytic involves a stability Tinplate this is unquestionably careful of, control, and quality assurance. Each batch of tinplate is subjected to assessment this is actually rigorous make sure that it satisfies probably the most effective requirements of quality. This strategy guarantees that this product that is last without the impurities and defects.

The Electrolytic Tinplate provides workability this is really very rendering that is good quite simple to make and contour into different shapes and sizes. Its workability enables it is contained in different organizations, from dishes packaging to construction materials. This product can be really very easy to cut, weld, and relationships.

The tin layer for the Electrolytic Tinplate can be highly resistant to corrosion, which makes it a option that is fantastic items which requires security that is lasting. The tin coating forms a barrier that is protects that are durable root steel from moisture, oxidation, along with other types of corrosion.

The Electrolytic Tinplate is an option that is very good terms of sustainability. The materials is recyclable and certainly are going to be reused times which can be numerous losing its properties. This reduces the requisite for virgin materials and minimizes the effect that is environmental of item's manufacturing procedure.

Get this now today.

Product Name |

Tinplate Coil |

Material |

MR SPCC SPCD SPCH Q195L S08AL SPTE etc. |

Standard |

ASTM AISI DIN JIS GB EN BS EN 10202, DIN EN 10203, GB/T2520, JIS G3303, ASTM A623 |

Temper |

T1/T2/T2.5/T3/T4/T5/DR7/DR7.5/DR8/DR9/DR9M/DR10,etc. |

Annealing |

CA(Continuous annealing) and BA(Batch annealing) |

Tin Coating (g/m2) |

1.1/1.1, 2.0/2.0, 2.8/2.8, 5.6/5.6, 8.4/8.4, 11.2/11.2, etc. |

Application |

Widely used for metal packaging industry. Such as making cans for food, tea, oil, paints, chemicals, aerosol, gifts, printing |

Thickness |

0.12-0.6mm |

Width |

600-1500mm |

Surface Finish |

Stone, Bright, Silver |

Quality |

Mill Test Certificate supplied with the shipment ,third party inspection is acceptable |

Excellent Corrosion Resistance

|

By selecting a proper coating weight,appropriate corrosion resistance is obtained against container contents.

|

Excellent Paintability & Printability |

Printing is beautifully finished using various lacquers and inks. |

Excellent Solderability & Weldability |

Tinplate is widely used for making various types of cans by soldering or welding. |

Excellent Formability & Strength |

By selecting a proper temper grade,appropriate formability is obtained for various applications as well as the required strength after forming. |

Beautiful Appearance |

Electrolytic ETP is characterized by its beautiful metallic luster.Products with various kinds of surface roughness are produced by selecting the surface finish of the subtrate steel sheet. |

A1: Free samples are available for your checking and testing. But you need to pay for the fligh cost.

Q2: Can you provide Mill Test Certificate?

A2: Yes! The Mill Test Certificate will be issued with the product.

Q3:Packing details?

A3:Packaged 25 Tons per 20 GP wooden case container.

20ft GP: 5898mm(Length)x2352mm(Width)x2393mm(High)

40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High)

40ft HC: 12032mm(Length)x2352mm(Width)x2698mm(High)

Q4:What is your terms of payment?

A4: 100% T/T advance.

30% T/T and balance against copy of documents.

30% T/T advance, balance L/C at sight.

Q5:Can we visit your factory?

A5: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

EN

EN

AR

AR

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LT

LT

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MK

MK

AZ

AZ

KA

KA

UR

UR

BN

BN

GU

GU

HA

HA

JW

JW

MI

MI

TA

TA

TE

TE

UZ

UZ