“Stainless Steel Girder Beams – An Ideal Solution for Your Building Needs”

Introduction:

Stainless steel girder beams are used in construction and engineering around the world. The material is made out of an alloy that is corrosion-resistant, containing at least 10.5% chromium which gives them their unique properties. In here we will discuss on benefits, innovation, safety, use, how to use it properly? service quality and application areas of Qingfatong Stainless steel beam.

There are many advantages of stainless steel girders over traditional materials like wood or concrete for example. One such advantage is its durability; being able to withstand extreme conditions and weathering unlike any other metal could do so freely without rusting away as well as decomposed by moisture overtime. Also Qingfatong h beams should be noted that these sections can be termed “green” since they can be recycled therefore no more trees need to die!

Innovation drives everything in the stainless-steel industry. Manufacturers are constantly trying new things in order to make Qingfatong stainless steel h beam stronger, last longer and work better. For instance: some lighter weight designs have been created which also happen to flex more easily making installation easier while reducing construction time required.

The use of stainless steel beams ensures safety compared with other conventional materials because Qingfatong 301 stainless steel coil fire resistant which means there’s no toxic gas released when burnt but also do not rot or grow mold etc., hence healthier choice for building work places too apart from being safer option than those prone to infestation by pests such as termites.

Steel structural members like these ones described here under section can be applied widely across different types buildings ranging from commercial establishments up through industrial plants down onto bridges connecting various parts cities underground via tunnels among others. its strength factor plus durability makes perfect material where heavy loads are to be supported such cranes moving over elevator shafts. Moreover Qingfatong 321 stainless steel coil sleek modern appearance makes them architectural favorite materials.

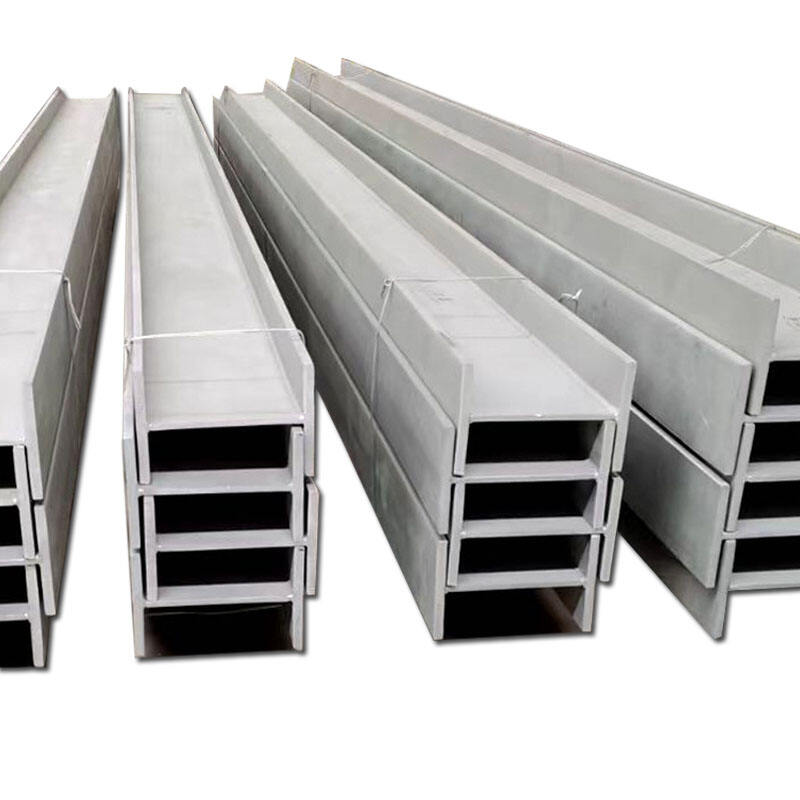

have complete product specification and various material,high dimensional accuracy up -0.1mm.Excellent surface quality good stainless steel beam,non-standard custom according demand.

We'll provide unique packaging, which increases the stainless steel beamrate goods transit.can also provide custom-designed packaging.

products supplied meet specifications offer most efficient cost stainless steel beam. inspections include raw material manufacturing supervision, product appearance inspections, final inspections.

have more than decade experience in supply stainless steel the international market.Enable fulfill any order within shortest period stainless steel beam.

The process of using Stainless Steel Girder Beams is similar to that of other steels. Qingfatong hot rolled stainless steel coil can be cut, welded or bolted on to different types of metals. When welding this material, it’s important one uses appropriate filler metal along with correct welding technique so as ensure solid joint which will last long. In addition care must also taken during transportation and installation not cause any scratches or dents which might weaken the beam.

You should expect a lot from manufacturers when purchasing these products because they are made out good quality Qingfatong stainless steel coil stock Industries who ought provide detailed product information i. e. technical data sheets inclusive installation guides etcetera; also offering customer support services whenever needed until completion your project meets required industry standards.

From an overall perspective all construction materials need satisfy certain standards – even more so with regard stainless-steel girder beams as well. Therefore choose only those beams meeting ASTM A588 and/or A992 among others where applicable while at same time ensuring that only high caliber Qingfatong 430 stainless steel coil were used during production process thereby ensuring both strength durability.