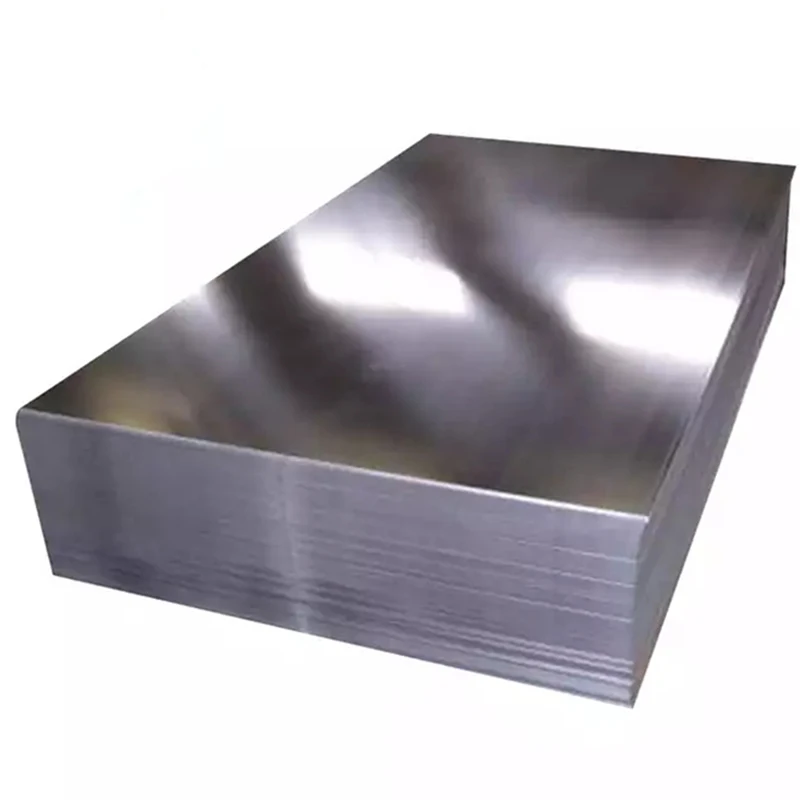

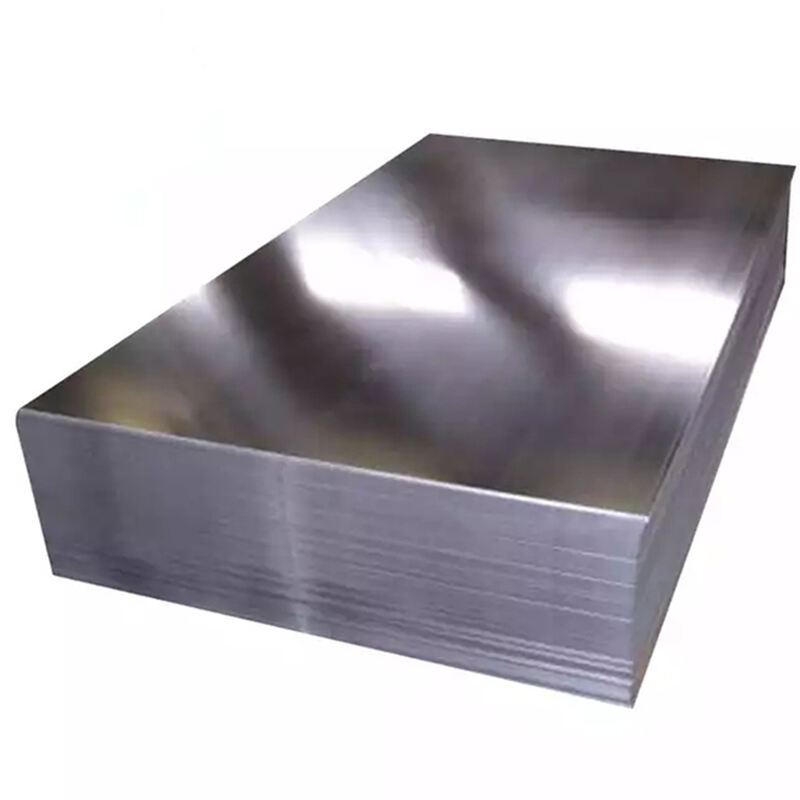

Electric tinplate metal sheets combine know and steel to create an exceptionally robust material. This makes them resistant to corrosion and easier to clean by ironing a layer of tin onto the sheets. This step not only increases the life of the sheets-thus lesser units for replacement, but also makes it more efficient in a kind on industrial back drop. This material has therefore been widely used in various industries due to its durability and long-term protection; such is the case, that it started being applied here at auto manufacturing sector as early back as 1992.

Electric Tinplate Sheets, because of its high versatility.

Different customers have different demand, it has a wide application range, they are widely applied for food cans, lubricant oil lug caps, Auto bottom cover and other components. These are safe to be in direct contact with food since they comply with strict regulations. They are known in electronics, as they create a faraday cage around electronic objects preventing signals from escaping or entering meaning that devices can perform easily without disruption. Furthermore, their pliability and versatility ensure that they are an essential tool in verifying the parting line corroboration method and this reinforces them as one of the most necessary equipment within a modern industrial environment where flexibility is key over just being active.

Focus on Quality and Safety

The quality of these electric tinplate sheets by Qingfatong is the key to guarantee customer satisfying and behaving safety criteria. From raw material to finishing stage, these sheets go through stringent quality control checks by the manufacturers throughout its life cycle. These producers maintain a high level of quality that ensures consumers and corporations in an already competitive landscape, take home the best end product possible which keeps them coming back again and again.

Encouraging environmental responsibility with tinplate sheet

WHAT IT MEANS: The move towards reusable tinplate sheets is a substantial leap forward from an environmental perspective as they are environmentally friendly and can be recycled. Tinplate sheet, on the other hand are 100% recyclable which makes them a more eco-friendly choice when compared to their non-coated alternatives that cause environmental problems. This recycle ability serves two purposes: it reduces waste and also saves energy, aligning with global sustainability goals as well as good resource management practices. The purchase of tinplate coil sheets is not only a win for global sustainability goals but also ethical consumer ideals; overall an all-around good decision.

Choose a Tinplate Sheets Suppliers That Gives Quality and Innovation

Consequently, you need to find the right tinplate sheet supplier who can understand how supply chain dynamics work and is committed towards achieving future success. The changing needs of customers have led suppliers to develop customized offerings by investing in R&D for better product performance and reduced use of virgin materials. Through their market knowledge and technical know-how, our partners provide a complete end-to-end supply chain experience that includes pre-sales consultation to after sales support. Partnering with reliable tinplate manufacturers also provides you immediate access to the newest in technology, and most significantly assurance of quality durability, performance as well as environmental sustainability that are all characteristics associated with modern day electrolytic tinplate coil.

EN

EN

AR

AR

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LT

LT

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MK

MK

AZ

AZ

KA

KA

UR

UR

BN

BN

GU

GU

HA

HA

JW

JW

MI

MI

TA

TA

TE

TE

UZ

UZ