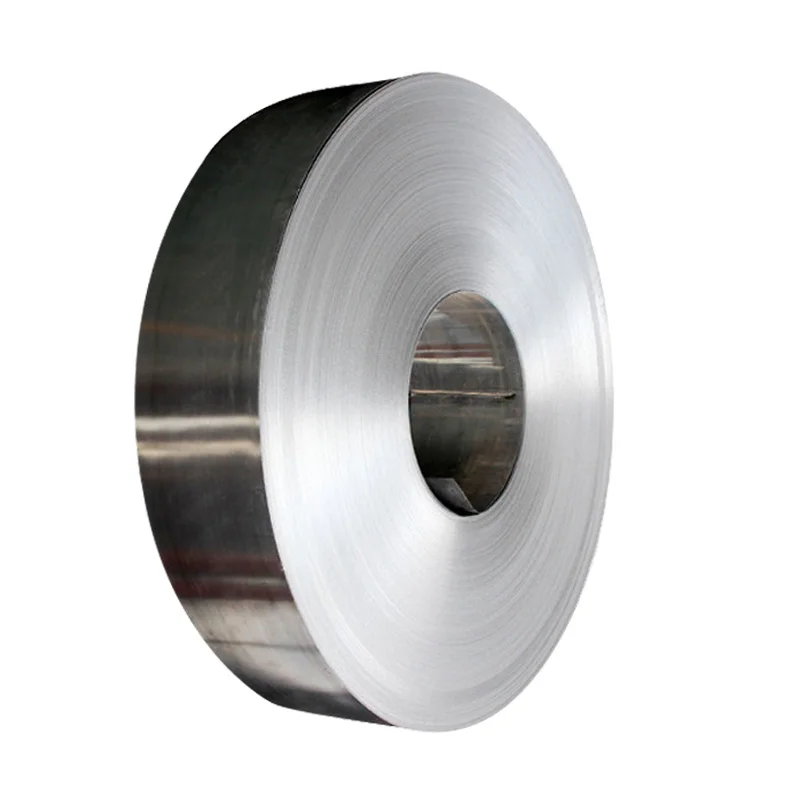

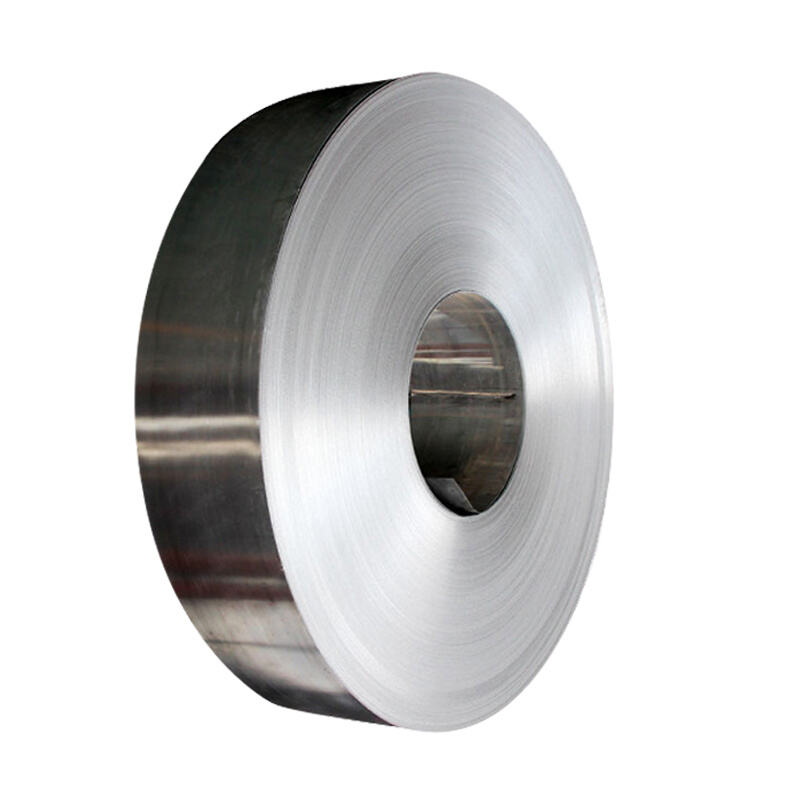

As a developed country, australia is renowned for its superb steel industry and offers the highest grade products possible to produce using advanced manufacturing processes. The most diverse and robust product in steel ages is galvanized iron (gi) coils. These coils are very useful in multiple sectors like construction, automobile purpose appliances and infrastructure projects. In this post, we are narrowing our focus on the best gi coil manufacturers in australia to take a closer look at their industry leading brands, sustainability efforts and innovations that distinguish them from rest of the market trends worldwide.

One of the best GI coil suppliers in Australia

Australia is home to a number of gi coil manufacturers that have not only stood the test of time, but are on continual quest for innovation and modern sustainability. All of these companies boast a unique combination of experience, innovation and commitment to quality that underpins their guarantee both are made in australia from and conform with more than simply international standards.

Top brands changing the game in gi coil manufacturing companies

Among the frontrunners is Qingfatong, a company that has been instrumental in helping to transform gi coil with its proprietary activate technology. This breakthrough increases the corrosion resistance of zinc coating resulting in an extension to structural life and savings on maintenance expenditures. Qingfatong also uses advanced, in-house equipment for high precision slitting and cutting solutions catered to a wide variety of customer requirements.

The diversification of works at liberty primary steel is underway with their why under an imagery digital modernization program to drive the implementation and use smart manufacturing systems, supporting optimization in resource efficiency. It places a high priority on the reuse and recycling of scrap metal, founded upon circular economy principles that support an overall more sustainable supply chain.

Leading suppliers of premium gi coils in Australia

With an industry as reliability-sensitive and safety-critical, customer confidence is pivotal. These manufacturers have built reputations by delivering time and again products that perform their best when the going gets tough. A great example of a product that demonstrates testing and research is the steel from Qingfatong, uses worldwide by builders and architects.

With one of the most extensive product ranges and efficient distribution networks in our industry, this is why many people count on. Additionally, an uncompromising quality-assurance approach throughout manufacturing gives liberty primary steel customers peace-of-mind and infrabuild's rigorous testing program ensuring the validity of stainless coil sold.

Top gi coil manufacturers and their green practices

Sustainability in today's manufacturing world is not just a choice but an obligation. Local producers of gi stainless steel coil are advancing solutions for more sustainable production in australia these initiatives include the water-jet cooling technology and smart integration of renewable energy sources to reduce greenhouse gas emission.

Across all of its operations, Qingfatong actively supports recycling programs that promote the reuse of steel products to protect valuable natural resources. Strategic investments in green technologies support liberty primary steel's key objectives to minimise waste and contributing emissions towards achieving global climate goals. Infrabuild, as noted earlier in this guide, is a circular economy advocate by providing the market with products and solutions that helps transform waste into riches smoothly integrating all steps of steel production from closed loop.

Australian firms in gi coil manufacturing

Spring sure galvanised colour contaminated (gi) coil and sheet market success is down to constant innovation, a commitment to the highest quality standards practicable while maintaining considerable environmental responsibility as well as knowing what their clients want. Australian manufacturers have moved beyond supplying a product to long term relationship supply partner, working closely with customers throughout the entire development process and creating solutions that are applicable to real world problems.

In addition, government funding for research and development combined with skilled workers really give the potential to continually get better. When they combine it with high-level industry 4.0 technologies and best-in-class environmental management practices, these companies are at the leading edge of gi coil production worldwide.

EN

EN

AR

AR

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LT

LT

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MK

MK

AZ

AZ

KA

KA

UR

UR

BN

BN

GU

GU

HA

HA

JW

JW

MI

MI

TA

TA

TE

TE

UZ

UZ