Electrolytic Tinplate: The Best Choice for Packaging Needs

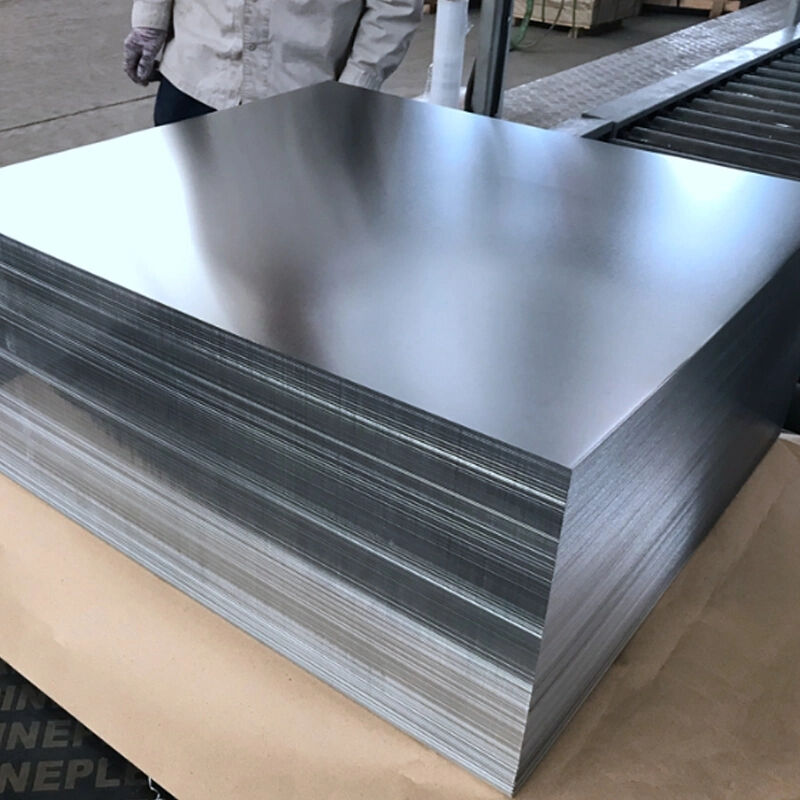

Electrolytic tinplate is a special type of product, made by coating tin on the surface of thin steel sheets through an operation of electrolysis. This Qingfatong electrolytic tinplate material is trusted in the food industry for packaging cans, it is a popular choice for manufacturers because it has its own advantages.

One of the major advantages of electrolytic tinplate is its excellent resistance to corrosion. Tinplate cans are durable and can withstand various external elements such as temperature, atmospheric pressure, and moisture. This Qingfatong electrolytic tinplate coil makes them a safe and reliable packaging choice.

Another benefit is the material's ability to be shaped into different sizes and shapes. Electrolytic tinplate allows manufacturers to produce cans in many different designs, from round to rectangular, and in various sizes to accommodate different packaging needs. This can help make food products look more appealing to consumers, as well as easier to transport and store.

In recent years, electrolytic tinplate has undergone numerous technological advancements to improve its quality and features. Qingfatong electrolytic tinplate sheets feature high levels of consistency in manufacturing, ensuring the material is of high quality and meets the requirements of various food products.

Additionally, researchers have developed many advanced methods for enhancing the production of tinplate by making it stronger, lighter, and more sustainable. For example, there have been recent innovations in coatings that use non-toxic materials to reduce greenhouse gas emissions, thereby protecting the environment.

Using electrolytic tinplate for packaging is considered safe, as it doesn't release toxic substances into the food contained within it. The Qingfatong tinplate coil acts as a barrier that separates the food from the steel, preventing any harmful toxins from leaching into the food.

The use of electrolytic tinplate also helps to protect food products from contamination and spoilage, as well as preventing oxidation and rusting of the cans over time. This ensures product safety and quality, allowing manufacturers to guarantee a longer shelf life and maintaining consumer trust in their products.

Using electrolytic tinplate is simple, and it can be processed and packaged in different ways according to the manufacturer's requirements. Typically, the Qingfatong prime electrolytic tinplate are first coated with a thin layer of tin using an electroplating process, and then they are formed into cans using specialized machinery.

Once the cans have been formed, they are thoroughly cleaned and sterilized before being filled with food products. The cans can also be labeled and decorated for branding purposes, allowing manufacturers to create unique and attractive packaging that will appeal to consumers.

will consider electrolytic tinplatepackaging.

products we offer meet the technical specifications deliver best value performance. Included are electrolytic tinplateraw materials and production oversight, well as appearance inspections, as well as final inspections.

have complete product specification various material,high dimensional accuracy to+-0.1mm.Excellent surface quality good brightness,non-electrolytic tinplatecustom according demand.

We have more than 10 years experience in the supply stainless steel materials the global market.Enable finish any order electrolytic tinplateshortest amount time.