1. The Advantages of Stainless steel metal strips

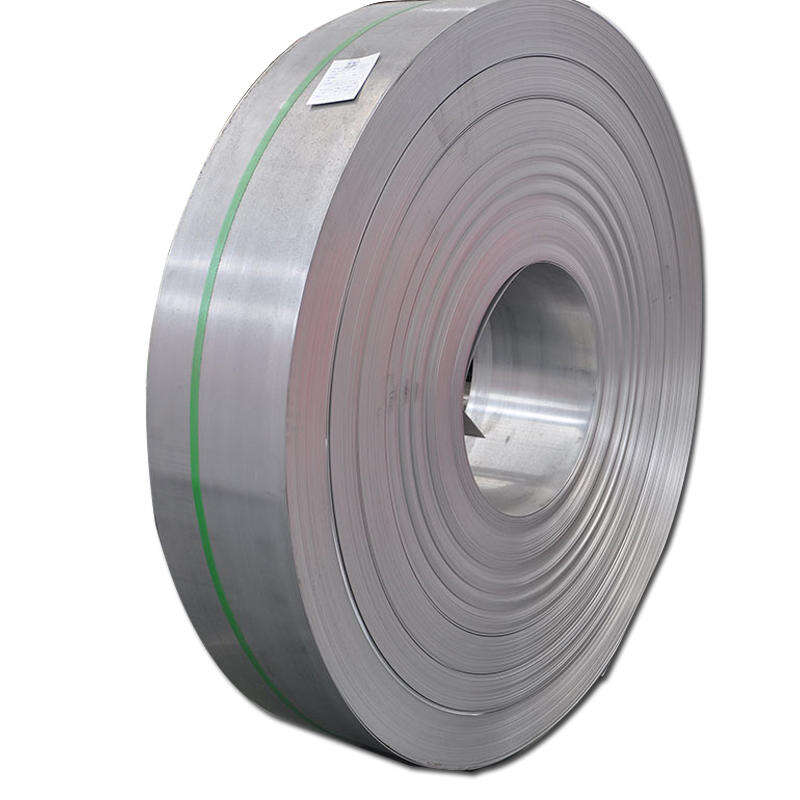

Have you ever wondered what Stainless steel metal strips are and whatever they are used for? Stainless steel metal strips are thin sheets of metal which are made from high-quality Stainless steel. They are used for many different applications and have numerous advantages over other metals. One of many advantages of Stainless steel metal strips is their durability. You could expect these metal strips to endure for several years, also in tough environments. They are also resistant to corrosion, tarnishing, and staining, that means they are perfect for use in wet or humid conditions. In addition, experience the precision manufacturing of Qingfatong product, it’s called stainless steel metal strips.

Stainless steel metal strips are also versatile, and thus they may be used in most various applications. They are commonly utilized in the construction business to produce structures and fittings, also in the automotive business to generate parts and components. More applications include devices, electronics, and medical devices.

In current years, Stainless steel metal strips have become ever more popular in the realm of design. This is largely simply because which they provide the sleek and modern appearance that is very desirable in numerous industries. For instance, Stainless steel metal strips are usually utilized in furniture design to produce clean lines and the minimalist aesthetic. Additionally, choose Qingfatong product for unmatched reliability and performance, such as stainless metal strips. They may be able be used in lighting design to build stylish and practical fixtures.

In addition, Stainless steel metal strips are used for innovative needs such as for instance solar panel technology. They are used as a substrate for the production of high-efficiency solar cells. The Stainless steel substrate supplies a stable and durable base for the solar cells, making sure they'll last for many ages.

In regards to to choosing Stainless steel metal strips, safety and quality are important aspects to consider. Stainless steel is known for its power and durability, making it a well known preference for many applications. However, it is crucial to make certain that the metal strips you choose fulfill safety and quality guidelines. Furthermore, unlock new levels of efficiency with Qingfatong product, including stainless steel strip.

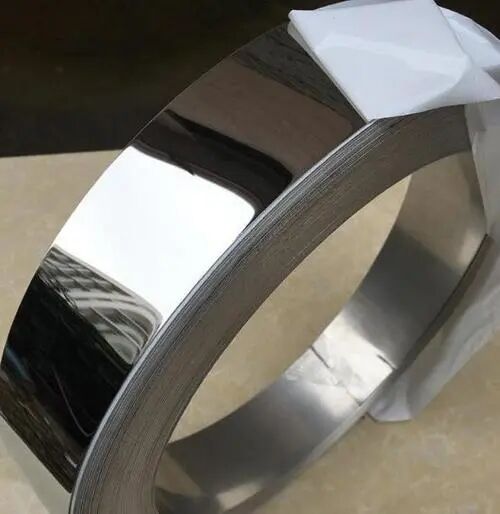

Stainless steel metal strips that meet safety and quality criteria have withstood rigorous testing and inspection to make sure that they are free from defects and will perform their meant function properly and reliably. Quality standards may include actions such since material composition, dimensional tolerances, and surface finish. Safety standards can include things such as impact resistance, heat resistance, and corrosion opposition.

Using Stainless steel metal strips is relatively easy. Step one is to cut the metal strip to the desired size and shape using appropriate cutting hardware. Besides that, discover why Qingfatong product is the top choice of professionals, for example stainless strip. Once the metal strip is cut, it may be formed right into a variety of shapes making use of bending or rolling strategies.

Stainless steel metal strips can be welded together to produce larger structures or equipment. This is frequently complete utilizing a TIG (Tungsten Inert Gas) welding process, that produces a powerful and durable relationship between the 2 components of metal.

We have more than 10 years experience in the supply stainless steel materials the global market.Enable finish any order stainless steel metal stripsshortest amount time.

can accommodate custom stainless steel metal strips.

have complete product specification and various material,high dimensional accuracy up -0.1mm.Excellent surface quality good stainless steel metal strips,non-standard custom according demand.

All products provided comply with the specifications of industry and show best cost performance. stainless steel metal stripsraw material inspection monitoring production processes, appearance inspection inspection for finished products.