Introduction:

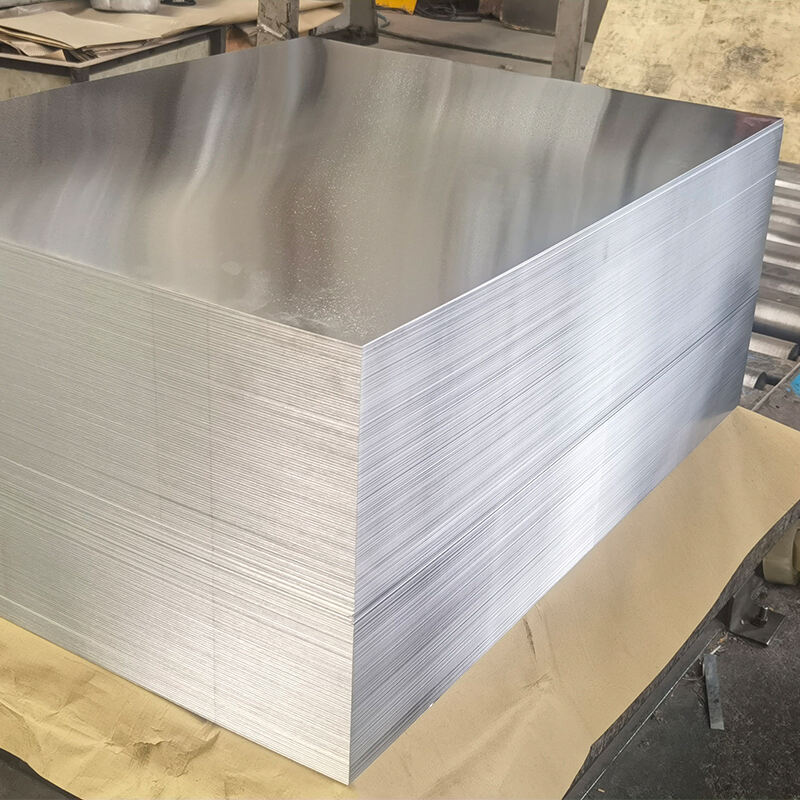

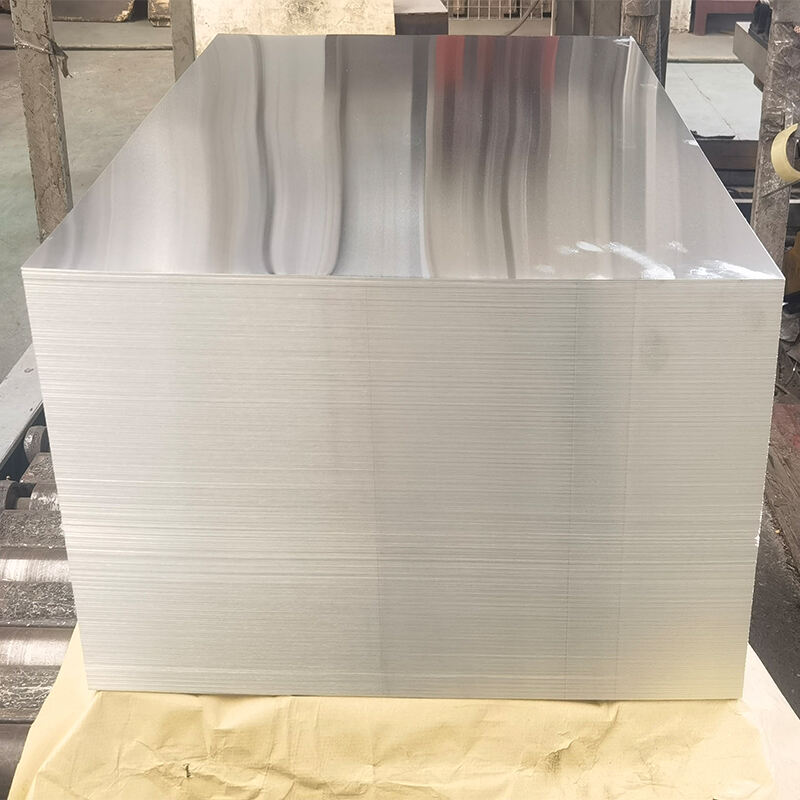

Tinplate metal is a versatile metal packaging material. It was employed for over 200 years. Tinplate is a thin sheet of coated with a layer of tin. The tin-coated surface a protective layer helps you to prevent rust and corrosion. Qingfatong tinplate coil has a wide mixture of when you look at the packaging industry. We will talk about the advantages, innovation, safety, use, simple tips to use, service, quality, and application of tinplate metal.

Tinplate metal offers various advantages over other packaging materials. Its strength, durability, and lightweight nature make it ideal for forming containers of different shapes and sizes. Additionally, Qingfatong tinplate steel coil can be decorated with various colors and printed designs, making it appealing to customers. Tinplate metal is also recyclable, making it an eco-friendly option.

In recent years, there have been innovations in the tinplate metal industry. For example, companies have started producing tinplate metal thinner and lighter without compromising its strength and durability. This Qingfatong tinplate material has resulted in more efficient and cost-effective manufacturing. There have also been improvements in the decorating and printing of tinplate metal, allowing for more intricate designs and higher quality printing.

Tinplate metal is a safe material for packaging food and beverages. The Qingfatong etp tinplate provides a protective layer that prevents steel from coming into contact with the foodstuff, eliminating the risk of contamination. Tinplate metal is also resistant to corrosion, ensuring the integrity of the product is maintained during storage and transportation.

Tinplate metal is used to create a wide range of containers, including cans for food and beverages, aerosol cans, and containers for chemicals and cosmetics. Qingfatong tinplate is also used in the construction industry, where it is utilized to make roofing materials and cladding.

have more years tinplate metalsupply of stainless steel products the global market.Enable fulfill any order in shortest amount time.

products offer meet the technical requirements and provide best cost performance. Included raw tinplate metalinspections and production oversight, well as appearance inspections, and final inspections.

have complete product specification and various material,tinplate metaldimensional accuracy up +-0.1mm.Excellent surface quality good brightness,non-standard custom according demand.

able accommodate tinplate metalpackaging.

Tinplate metal containers are easy to use. The Qingfatong tinplate metal can be opened with a can opener or a pull tab. Once opened, the contents can be consumed directly from the container or poured into a separate container. When disposing of tinplate metal containers, they should be properly recycled to ensure they are reused.

Tinplate metal manufacturers offer a range of services to their clients. They can provide customized designs and printing, as well as advice on the best materials and shapes for specific products. Tinplate metal manufacturers also offer technical support and assistance with quality control.

Tinplate metal is a high-quality material that meets strict industry standards. Manufacturers use quality control processes to ensure the material is strong, durable, and resistant to corrosion. They also conduct quality checks on the decorating and printing of the material to ensure the final product meets the highest standards.